Saveh White cement factory

Year of establishment: 1988

Production rate: 1000 tons per day

Production line: design and installation of FCB France

SAVEH White Cement Factory was established in November-December 1988 with a capacity of 500 tons per day, and with the implementation of the development plan, its capacity has increased 1000 tons per day. The technology used in the factory of white cement production is obtained from F.C.B. This technology is based on “wet” production and its use for cement production increases the degree of whiteness above 92% and increases its mechanical strength, too. The white cement production line was designed and installed by FCB France.

Procedures and equipment

White cement production line

Crusher

- Hammer Crusher with a capacity of 200 tons per hour, model CMP 5.5N, made by F.C.B, France.

- Jaw Crusher with a capacity of 50 tons per hour, model BW 80, made by BABBITLESS, Germany, which is effective for crushing kaolin, silica, and gypsum up to dimensions below 12 cm.

- Cone Crusher gyratory with a capacity of 40 tons per hour, model BS702-6, made by BABBITLESS, Germany. It is used for crushing kaolin, silica and gypsum up to dimensions below 12 cm.

Mixing room

- The mixing hall of this complex includes two piles with a capacity of 8000 tons each.

Material mill

- This department has a two-chamber pellet mill of the middle discharge type, made by the French F.C.B company, with a capacity of 90 tons per hour.

Preheater and oven

- Each of the production lines of this factory has a 2-stage preheater with a capacity of 500 tons per day, and also has a 500-ton furnace made by F.C.B France.

Cement mill

- This company has a ball mill machine with a capacity of 45 tons per hour, with dimensions of 11 x 3.4 m, made by F.C.B, France, UMS-Closed circuit model.

Loading dock/place

- In the part of the warehouse, the Rotary Packer type with a capacity of 90 tons per hour was designed and manufactured by HAVER&BOECKER Co. in Germany.

How to prepare white cement

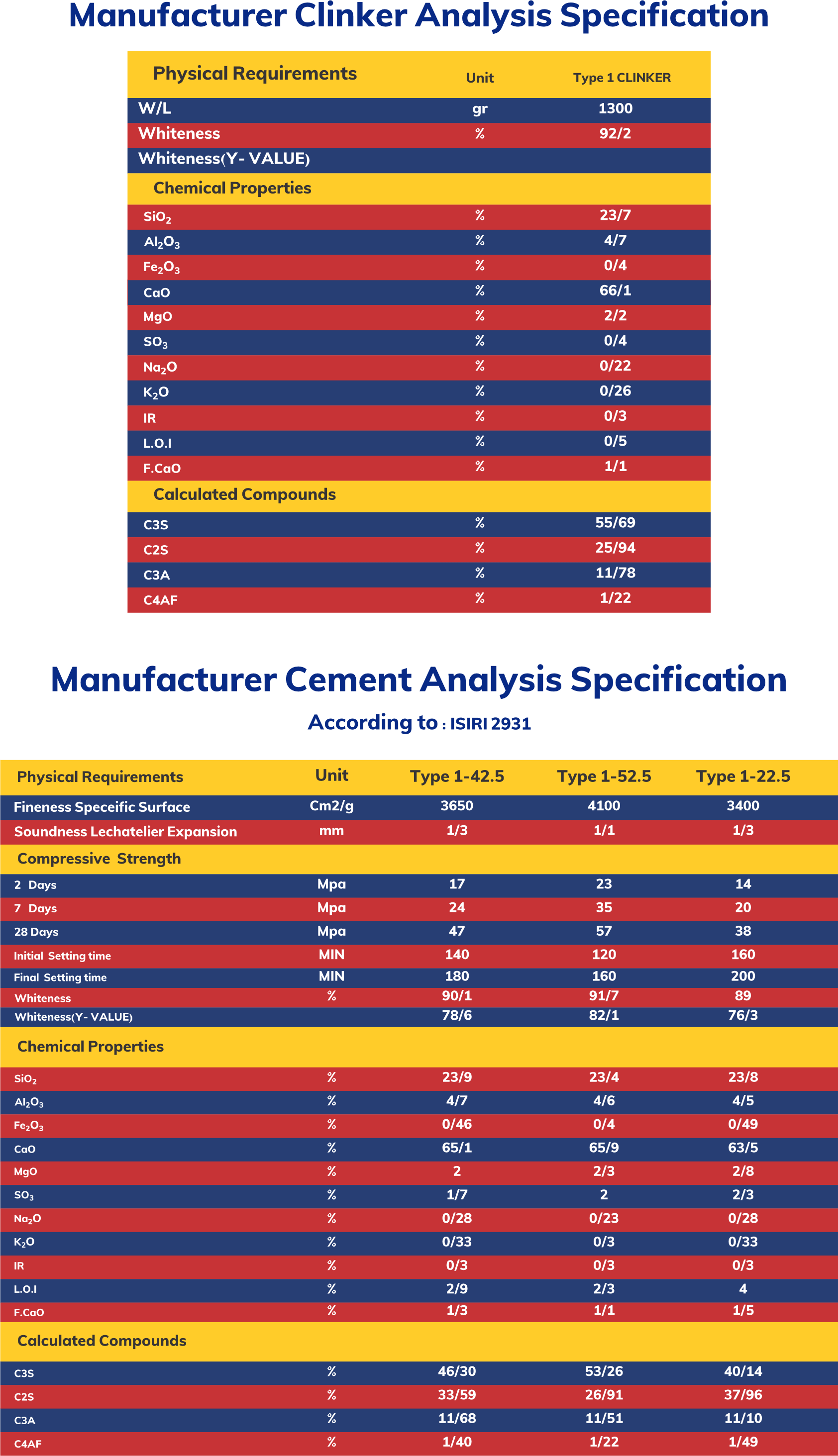

There is a kind of complexity in the production and manufacture of white cement compared to gray cement, and many materials other than lime are needed to whiten the color of cement. Therefore, colored elements such as iron oxides, chromium, titanium and manganese should be zero in the raw materials. For this purpose, you should use limestone with high purity and quality, as well as white kaolin, which does not contain colored oxides. The first step for the production of cement is the preparation of high-quality clinker, which will lead to the production of white clinker in the process of baking in the oven. It should be noted that in the next step, when the clinker is crushed in the mill, some gypsum is used to whiten and increase the strength of the product (cement).

Ru

Ru Fa

Fa En

En Ar

Ar